PROFESSIONAL 3D PRINTERS

Our solutions for precision 3D printing

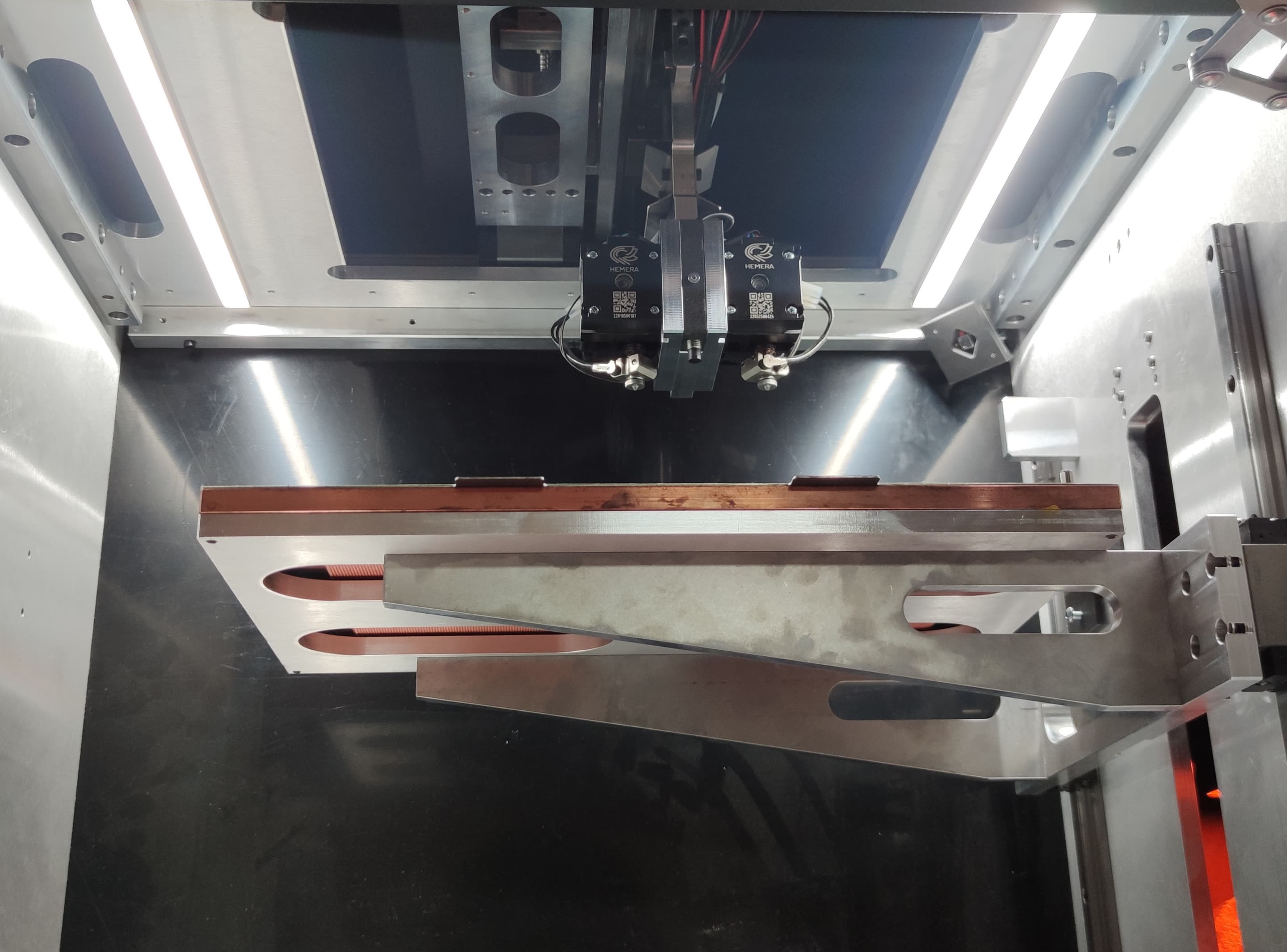

PREMIA 300 Professional Printer

Professional FDM printer, designed for high-precision and industrial applications.Engineered to meet all the requirements of professional and industrial processes where high-precision or technical polymers, thanks to its unique motion system and high temperature hotend and heated bed. Tecna 230B will give your product the importance it deserves without compromises or wastes of time. Request a QUOTE

TECHNICAL FEATURES

-

MOVEMENT

The foundations of precise motion control

Centered and referenced Peraluman 5083 aluminum plates to ensure stability and secure references for motion control. -

MECHANICS

Industrial mechanics for high positioning repeatability

Screws and ball-bearing slides to provide enhanced safety during motion. - EXTRUDER

Dual Drive Extruder and Full-Metal Hotend with bed leveling control

Maximum temperature of 450°C, interchangeable nozzles in either brass or hardened steel in various sizes (standard 0.4mm included). Inductive sensor and bed leveling matrix control for the printing surface, with software correction of anomalies.

-

HEATED BED

Copper plate beneath the harmonic steel print surface

Equipped with a heaterfor the printing surface that can reach up to 200°C, creating a 70°C air column around the printed part.

A PEl coating on the printing surface ensures part adhesion, while its flexibility facilitates easy removal.

-

FILAMENT CONTROL

Filament drag and presence sensor to prevent interruptions during printing. -

SENSORLESS STALL DETECTION

Upgraded stepper motors with step loss detection to ensure maximum accuracy.

-

PRINTING VOLUME

300 x 230 x 230 mm -

DRYING

Filament Drying for clean prints

Insulated and heated storage compartment for spool storage. -

RESULT CHECK

A constant view of the manufacturing process

Dual high-resolution cameras, one positioned at the first layer level and the second for an overall view of the printed piece.

Tecna 230B Professional Printer

Professional FDM printer, designed for high-precision and industrial applications.Engineered to meet all the requirements of professional and industrial processes where high-precision or technical polymers, thanks to its unique motion system and high temperature hotend and heated bed. TECNA 230B will give your product the importance it deserves without compromises or wastes of time. Request a QUOTE

TECHNICAL FEATURES

- CHASSIS

External structure in Peraluman 5083 alluminum alloy built with 10mm thick milled plates with H7 centering pins - MOVEMENT

3D Evolve patented high precision movement system built on industriai grade ball bearing guides and screws.

Axis positioning repeatability ±-0.001 mm. Stepper motors with 8.2 Kg / cm torque and 2A/phase current. The motors are driven by Trinamics drivers designed to withstand high currents, automatic interpolation (up to 256 microstep) and stall detection lor step loss compensation. - EXTRUDER

Dual Drive extruder and Full-metal hotend designed lor operation at high temperatures (up to 550° C) and interchangeable nozzles (a standard 0.4 mm nozzle in hardened steel thai also allows the printing of high abrasion materials such as carbon addicted polymers is included). The enti re extruder group is hot swappable.

- HEATED BED

High temperature 3D Evolve copper heated bed, reaching temperatures up to 200° C, with excellent heating times and thermal stability. - STOP SYSTEM

Sensorless end stops system -does noi use mechanical parts to ensure durability and accuracy over time. - CALIBRATION

Automatic Z-axis height calibration with an inductive sensor.

lt allows to calculate a precise map of the heights in different points of the printing plane and automatically adjust the movements of the print head to compensate any difference in the flatness of the surf ace.

- BUILD VOLUME

230 x 230 x 230 mm - PRINTING SURFACE

Flexible spring steel printing surface to ensure the besi adhesion of all materials without the need lor aids. The plate is flexible and is secured to the printing plate by a matrix of magnets thai hold it firmly in piace.

The piece can be removed easily by bending the plate. - NETWORK CONTROL SYSTEM

Network control system via ethernet network or using the integrated 7" LCD monitor.

Remote management Industria 4.0 compliant.

- SENSORE

Filament runout sensor

FILAMENTS

ABS

PLA

FiloFlex

BioFlex

ABS Speciale

AlfaPRO

Grafylon

Thermec Z3D

Thermec Support

VetroAlfa

AlfaOHM

AlfaOMNIA

PET-G

PC/ABS SUPPORT

ABS 10^8 (Antistatic)

ABS V0 (Flame retardant)

n - ASA

Nylon

AlfaNylon CF

APPLICATION FIELDS